How Much Inventory Should I Hold?

In today’s volatile environment, inventory management isn’t just about efficiency—it’s about resilience. For manufacturers, logistics operators, and retailers, the right inventory strategy can mean the difference between thriving and struggling during supply chain shocks.

Why are inventory levels important?

Inventory ties up cash. Too much inventory increases holding costs, storage space, reduces efficiency, increases wastage and increases obsolescence. Too little inventory, and you risk lost sales and unhappy customers. The challenge is finding the balance between cost control and business continuity.

Work in Progress is the Hidden Trap

Recently a client came to visit with some good news. His sales forecast for the current year was 5% higher than the previous year, and the following year’s forecast indicated even higher growth, while maintaining gross profits at similar levels. But he was struggling with cashflow.

Growth often stretches cashflow. Where was the cash? There were jobs partly processed throughout the production facility, so work in progress was at the highest it had ever been. It’s not just raw materials and finished goods inventory. Work in progress (WIP) can lock up significant capital. Machine time and labour invested in unfinished jobs aren’t recoverable until goods are sold. If lead times blow out, WIP can balloon, choking cash flow. Tight job management and process efficiency are critical.

What is Economic Order Quantity (EOQ)? A Starting Point

Economic Order Quantity is the quantity of stock you should order each time to balance ordering costs and holding costs. Ordering costs are incurred every time you place an order, the administrative time and shipping freight or courier costs. Holding costs are the cost of storing goods, warehousing, insurance, security, depreciation and borrowing.

There are limitations to Economic Order Quantity. It assumes that demand and lead times are constant. It doesn’t allow for bulk order discounts or seasonal fluctuations in availability or price, like in horticulture.

Economic Order Quantity (EOQ) Formula

Where:

· D = Annual demand (units per year)

· S = Ordering cost per order

· H = Holding cost per unit per year

Example Calculation

If:

· Annual demand = 10,000 units

· Ordering cost = $50 per order

· Holding cost = $2 per unit/year

Source: Copilot

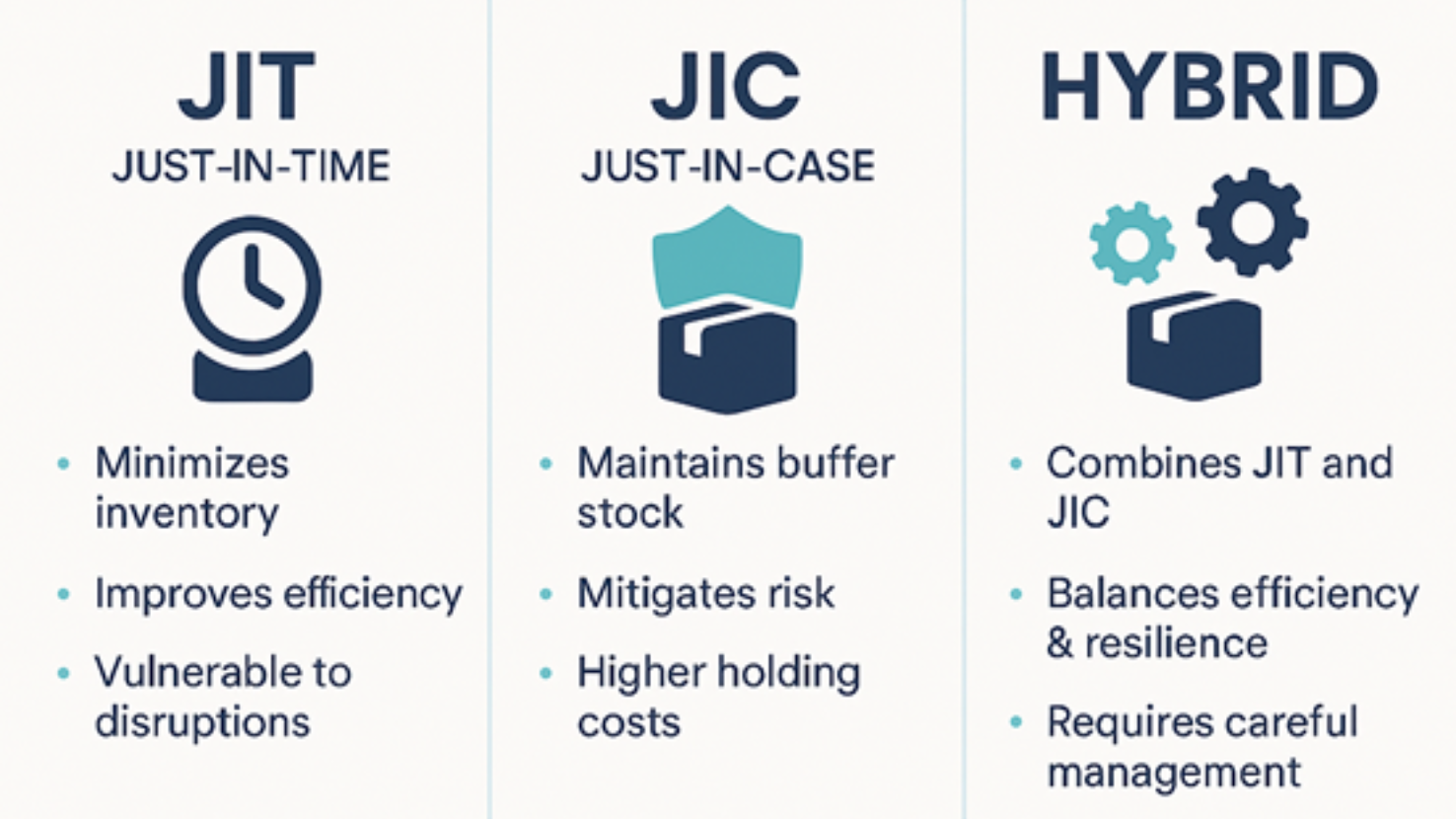

Should we use Just-In-Time (JIT) or Just-In-Case (JIC)?

What is Just-In-Time (JIT) Inventory Management?

Just-In-Time methodology was developed by Toyota Motor Corporation soon after World War 2. JIT’s core principles are takt time, the production pace required to meet customer demand; one-piece flow, continuous production instead of batching and accumulating inventory; pull-production, only producing what the following requires; quality at source, detecting and correcting issues at their origin rather than waiting on inspections; setup time reduction¸ minimising idle times to enable smaller batch sizes; kaizen, continuous process improvement encouraging all employees to reduce waste.[i]

Advantages of JIT Inventory Management

JIT’s demand-driven approach is essential for lean manufacturing. You have better efficiency and synchronization, shorter lead times, better quality and less wastage. You can be more agile to adapt to changes in customer demand.

Supply Chain Risk to JIT

The Covid-19 pandemic, Suez Canal closure and large scale weather events have exposed the shortcoming of JIT. When supply chains are majorly disrupted, you could find yourself short of key components very quickly.

Just-In-Case (JIC)

Many companies have adapted to JIT’s shortcomings by shifting to a hybrid model of combining JIT with strategic stockpiling.[ii] They hold larger stocks of key materials or components to boost their resilience against possible shortages.

[i]

https://kaizen.com/insights/jit-efficiency-supply-chain

[ii] https://itsupplychain.com/from-just-in-time-to-resilience-how-covid-19-other-disruptions-are-redefining-supply-chain-management

Near Shoring or Onshoring

A survey of US companies showed that 80% want to increase onshoring or nearshoring, to improve their supply chain resilience.[iii] Bringing goods closer to New Zealand is less practical, given our geographic distance from other markets. Instead, we should look at regional partnerships with our nearest neighbours in Australia and the Pacific. Invest locally in advanced manufacturing and automation. Use digital tools for planning and enhancing our offerings.

[iii]

https://www.bain.com/insights/nearshoring-overcoming-the-obstacles

Technological Solutions

There is a move towards using AI predictive analytics to forecast demand and predict disruptions. Smart warehousing and the Internet of Things (IOT) allows you track your inventory from anywhere in real time. Blockchain systems track goods along the supply chain, improving tracking, fraud protection and compliance to standards and regulations.

Improving Your Inventory Management

You can improve your inventory management by using an iterative approach, but you also need to review your system holistically. Do you have the right systems in place to identify and solve issues?

My client decided to add new equipment to reduce his production bottleneck. Some businesses may need to redesign their process and factory layout to reduce stock movements and improve efficiency. Others need to work on workplace culture to instil the tenets of continuous improvement, quality at source and getting the job done.

Calculate your EOQ and review safety stock levels. Identify and mitigate supply chain vulnerabilities. Research into technological solutions to improve your agility, planning and product offering. It’s not a cost cutting process. Find your balance between efficiency and resilience, so that you can grow with confidence.

- Serena Irving

Serena Irving is a director in JDW Chartered Accountants Limited, Ellerslie, Auckland. JDW is a professional team of qualified accountants, business consultants, tax advisors, trust and business valuation specialists.

Download a PDF version here or contact the author by email. Like our Facebook page for regular tips.

An article like this, which is general in nature, is no substitute for specific accounting and tax advice. If you want more information about the issues in this article, please contact your adviser or the author.